Standard Description

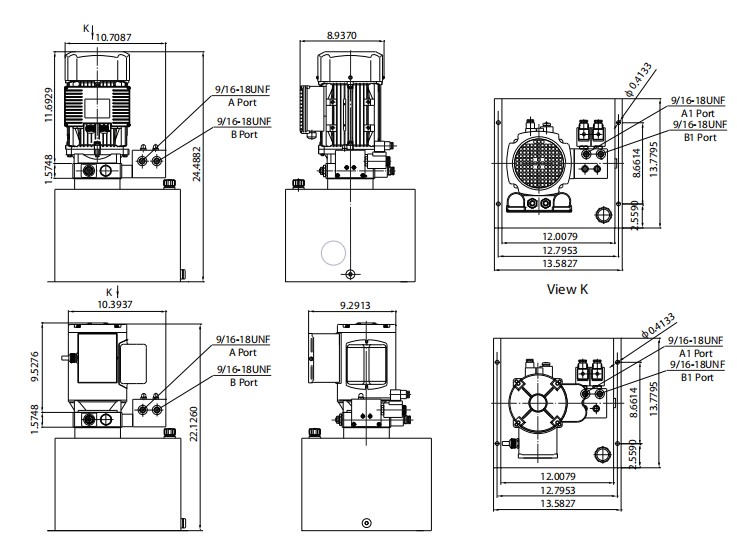

Equipped with the zero leak bidirectional checking sole-noid valves, this energy unit is built for your operation of two independent circuits. Which are respectively to the principal and subordinate platforms  with the double scissors lift. Two cut-off valves are applied for lowering the machine manually in case of energy reduction. If extra independent circuits are expected for your application please speak to us for availability.

with the double scissors lift. Two cut-off valves are applied for lowering the machine manually in case of energy reduction. If extra independent circuits are expected for your application please speak to us for availability.

Remark: one. Please seek the advice of our product sales engineer to the distinct pump displacement, motor power or tank capacity.

2. CSA or UL certified motors are available on request.

Distinctive Notes

one. The AC motor is of S3 duty cycle, which might only get the job done intermittently and repeatedly, i.e., 1minute on and 9 minutes off.

two. Clean all the hydraulic components concerned prior to installation of the energy unit.

three. Viscosity with the oil shoud be 15~46 cst,as well as the oil should be clean and free of impurities,N46 hydraulic oil is advised.

4. The power unit must be mounted vertically.

five. Check the oil level within the tank after the original running with the electrical power unit.

6. Oil transforming is required just after the initial one hundred operation hours,afterwards as soon as every 3000 hours.

Beam Coupling

As one of leading beam coupling manufacturers, suppliers and exporters of mechanical products, We offer beam coupling and many other products.

Please contact us for details.

Mail:[email protected]

Manufacturer supplier exporter of beam coupling.

Recent Posts

- China Good quality Flexible Beam Coupling Shaft Coupling

- China manufacturer Building/Bridge Construction Use Steel Material Fixing/Top Beam/Section Steel/Bracket Connection Coupling with Zinc Coating

- China high quality Flexible Coupling Aluminum CNC Parts Beam Coupling

- China Best Sales Auto Parts Multi Sizes Spline Coupler Spiral Beam Shaft Couplings

- China Standard High Torsional Stiffness Low Inertia Radial Beam Coupling Jt Series

- China high quality Building Construction Use Alloy/Carbon Steel Top Beam Connection Coupling with Zinc Coating

- China manufacturer Top Quality Stock Fast Delivery All Type Aluminum Alloy PU Coupling Jaw Beam Metal Bellow Shaft Couplings

- China Standard Hot Sale China Manufactured OEM Aluminum Beam Oldham Disc Jaw Metal Bellows Rigid Shaft Coupling

- China Custom Construction Pipe Seismic Bracing System Parts Base/Pedestal Fixing Top Beam/Section Steel Connection Coupling

- China best Office Building/Market/Hotel Water Gas Pipeline Seismic Bracing Set Accessories Base Beam Fixed Support Rod Coupling

- China Good quality Flexible Encoder Coupler Motor Shaft Coupler Clamp Beam Coupling

- China Best Sales Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Flexible Gear Coupling

- China supplier Flexible Coupling Aluminum CNC Parts Beam Coupling

- China Custom Flexible Beam Spiral Motor Shaft Coupling

- China Professional Construction Pipe Seismic Bracing System Parts Base/Pedestal Fixing Top Beam/Section Steel Connection Coupling

- China manufacturer Customizable Scaffold Beam Connectors BS1139 Standard Couplings

- China Custom Building Construction Use Alloy/Carbon Steel Top Beam Connection Coupling with Zinc Coating

- China wholesaler Building/Bridge Construction Use Steel Material Fixing/Top Beam/Section Steel/Bracket Connection Coupling with Zinc Coating

- China best Flexible Shaft Chain Coupling Rigid Bellow Grid Beam Tyre Roller Fluid Jaw Compliant Mechanism Oldham Coupler Rag Joint Universal Joint Dis Motor HRC Coupling

- China Hot selling Good Quality D20 L32 5mm to 12mm Flexible Beam Coupler Aluminium Metal Bellow Shaft Coupling

- China wholesaler Museum/Library Water Pipeline Seismic Bracing Set Accessories Base/Pedestal Fixing Beam Column/Section Steel Coupling

- China Best Sales Stainless Steel Aluminum Miniature Flexible Beam Coupling Encoder Coupling

- China Best Sales Good Quality Flexible Beam Coupling for CNC Machine

- China Hot selling Best Price Beam Disc Coupling Flexible Mechanical Jaw Coupling with Elastomer D30 L40-30c for CNC Router

- China high quality Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Flexible Gear Coupling

- China high quality Drive Pipe Spline Shaft Disc Flange Gear Rubber Jaw Motor Spacer Beam Rigid Fluid Chain Nm Mh HRC Pin Fenaflex Spacer Elastomeric Flexible Gear Coupling

- China supplier Top Quality China Manufactured OEM Aluminum Beam Oldham Disc Jaw Metal Bellows Rigid Shaft Coupling

- China best Clamp Type Spiral Beam Coupling for Printing Machines

- China high quality Hot Sale Mighty Aluminum Beam/Rigid Coupling CNC Flexible Jaw Plum Coupling with Red Rubber

- China Best Sales CNC Machining Milling Turning Aluminum Stainless Steel Low Force Link Slimline Strain Sensor Connect Body Liner Stage Liner Stage Thread Adaptor Beam Coupling

- China wholesaler Stainless Steel Aluminum Miniature Flexible Beam Coupling Encoder Coupling

- China Good quality Good Quality Flexible Beam Coupling for CNC Machine

- China supplier Flexible Shaft Chain Coupling Rigid Bellow Grid Beam Tyre Roller Fluid Jaw Compliant Mechanism Oldham Coupler Rag Joint Universal Joint Dis Motor HRC Coupling

- China high quality Building/Bridge Construction Use Steel Material Fixing/Top Beam/Section Steel/Bracket Connection Coupling with Zinc Coating

- China supplier Construction Pipe Seismic Bracing System Parts Base/Pedestal Fixing Top Beam/Section Steel Connection Coupling

- China OEM Flexible Coupling Aluminum CNC Parts Beam Coupling

- China Hot selling Best Price Beam Disc Coupling Flexible Mechanical Jaw Coupling with Elastomer D30 L40-30c for CNC Router

- China high quality Flexible Beam Shaft Spring Type Clamping Screw-up Beam Coupling

- China Best Sales Flexible Beam Spiral Motor Shaft Coupling

- China manufacturer CNC Machining Milling Turning Aluminum Stainless Steel Low Force Link Slimline Strain Sensor Connect Body Liner Stage Liner Stage Thread Adaptor Beam Coupling

- China Professional Stainless Disc Flexible Beam Coupling Encoder Coupling

- China manufacturer Flexible Coupling Aluminum CNC Parts Beam Coupling

- China factory Transmission Parts Flexible Universal Ship Shaft Flange Flexible Rub Double Standard Rigid Jaw Beam Universal Shaft Aluminum Roller Chain Coupling

- China Professional Radial Beam Flexible Coupling Nice Quality with Best Price

- China wholesaler Office Building/Market/Hotel Water Gas Pipeline Seismic Bracing Set Accessories Base Beam Fixed Support Rod Coupling

- China manufacturer Standard Steel Flexible Tubular Helical Beam Couplings

- China manufacturer Best Price Mighty Wholesale High Speed Aluminum Helical Flexible Beam Shaft Coupling

- China OEM Auto Parts Multi Sizes Spline Coupler Spiral Beam Shaft Couplings

- China Custom Museum/Library Water Pipeline Seismic Bracing Set Accessories Base/Pedestal Fixing Beam Column/Section Steel Coupling

- China Standard Auto Parts Multi Sizes Spline Coupler Motor Connector Spiral Beam Shaft Couplings

- China best Hot Sale Mighty Setscrew Coupling and Aluminum Helical Parallel Clamp Flexible Beam Couplings

- China supplier Construction Pipe Seismic Bracing System Parts Base/Pedestal Fixing Top Beam/Section Steel Connection Coupling

- China wholesaler Clamp Type Spiral Beam Coupling for Printing Machines

- China best Transmission Parts Flexible Universal Ship Shaft Flange Flexible Rub Double Standard Rigid Jaw Beam Universal Shaft Aluminum Roller Chain Coupling

- China Hot selling Customizable Scaffold Beam Connectors BS1139 Standard Couplings

- China factory Office Building/Market/Hotel Water Gas Pipeline Seismic Bracing Set Accessories Base Beam Fixed Support Rod Coupling

- China OEM Top Quality Stock Fast Delivery All Type Aluminum Alloy PU Coupling Jaw Beam Metal Bellow Shaft Couplings

- China manufacturer Top Quality Stock Fast Delivery All Type Aluminum Alloy PU Coupling Jaw Beam Metal Bellow Shaft Couplings

- China high quality Good Quality Flexible Beam Coupling for CNC Machine

- China factory Museum/Library Water Pipeline Seismic Bracing Set Accessories Base/Pedestal Fixing Beam Column/Section Steel Coupling

- China wholesaler Office Building/Market/Hotel Water Gas Pipeline Seismic Bracing Set Accessories Base Beam Fixed Support Rod Coupling

- China supplier Museum/Library Water Pipeline Seismic Bracing Set Accessories Base/Pedestal Fixing Beam Column/Section Steel Coupling

- China high quality Hotel/Office Building/Library Water Liquid Gas Pipe Seismic Bracing System Fittings Base Fixing Top Beam/Section Steel Coupling

- China Best Sales Building/Bridge Construction Use Steel Material Fixing/Top Beam/Section Steel/Bracket Connection Coupling with Zinc Coating

- China Good quality CNC Motor Helical Shaft Coupler Beam Coupling Connect Encoder

- China Standard Auto Parts Multi Sizes Spline Coupler Motor Connector Spiral Beam Shaft Couplings

BeamCoupling

As one of beamcoupling manufacturers, suppliers and exporters of mechanical products, We offer beamcoupling and many other products.

Please contact us for details.

Manufacturer supplier exporter of beamcoupling.