The group has taken part in the making and revising of ISO/TC100 international chain standard several years in success and hosted the 16th ISO/TC100 International annual meeting in 2004.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant, farms, Construction works , Flexible Mechanical Nylon Sleeve Gear Coupling

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- material:

-

nylon +45#steel

- Product name:

-

Nylon Teeth Sleeve For Gear Coupling

EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport.

- Application:

-

Mining Machiner

- Type:

-

Gear Coupling

- Color:

-

White

- Certification:

-

ISO9001:2008

- Body Material:

-

45#steel

- Size:

-

Standard Size

- MOQ:

-

1 Set

- DELIVERY TIME:

-

15-20 days

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Standard export package and wooden case

- Port

- TIANJIN

-

Lead Time

: -

Quantity(Pieces) 1 – 9999 >9999 Est. Time(days) 12 A PTO shaft transfers the power from the tractor to the PTO powered attachment. This enables the tractor to power a variety of tractor implements including flail mowers, wood chippers, rotary tillers, excavators, and more.

To be negotiated

Online Customization

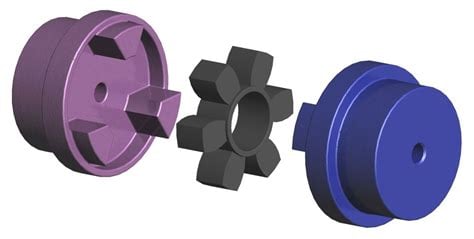

A gear coupling is a mechanical device for transmitting torque between two shafts that are not collinear. It consists of a flexible joint fixed to each shaft. The two joints are connected by a third shaft, called the spindle.

Each joint consists of a 1:1 gear ratio internal/external gear pair. The tooth flanks and outer diameter of the external gear are crowned to allow for angular displacement between the two gears. Mechanically, the gears are equivalent to rotating splines with modified profiles. They are called gears because of the relatively large size of the teeth.

Gear couplings and universal joints are used in similar applications. Gear couplings have higher torque densities than universal joints designed to fit a given space while universal joints induce lower vibrations. The limit on torque density in universal joints is due to the limited cross sections of the cross and yoke. The gear teeth in a gear coupling have high backlash to allow for angular misalignment. The excess backlash can contribute to vibration.

Gear couplings are generally limited to angular misalignments, i.e., the angle of the spindle relative to the axes of the connected shafts, of 4-5°. Universal joints are capable of higher misalignments.

Advantages of EPT gear coupling

1. Lowest price based on large scale production.

2. High and stable quality level.

3. Widely used in various mechanical and hydraulic fields.

4. Compensation for axial, radial and angular misalignment.

5. Convenient axial plugging assembly.

6. No brittlement at low temperature.

7. Good slippery and frictional properties.

8. Resistance to chemical corrosion.

9. Rich experience working with big companies in this field.

Nylon gear flexible coupling is the latest product,it has been using by abroad,and it is designed by mechanical committee of Jinan Casting forging machinery institute.

Features of NL gear coupling:

1.Absorb parallel,angular and axial misalignments

2.Simple assembly and disassembly

3.Easy maintenance and low noise

4.High tansmission efficiency

5.Long service life

| Model | Parameter |

| NL1 | Teeth:20 D=40MM D1=D2=26MM L3=34MM |

| NL2 | Teeth:28/45 D=42MM D1=D2=36MM L3=40MM |

| NL3 | Teeth:34 D=66MM D1=D2=44MM L3=46MM |

| NL4 | Teeth:45 D=83MM D1=D2=58MM L3=48MM |

| NL5 | TeGear Motions is capable of manufacturing worm gears in both standard and custom sizes. Our highly skilled team utilizes their many years of experience and our sizeable fleet of equipment to produce high quality gears with great precision.eth:38 D=93MM D1=D2=68MM L3=50MM |

| NL6 | Teeth:40 D=100MM D1=D2=68MM L3=52MM |

| NL7 | Teeth:36/45 D=115MM D1=D2=80MM L3=60MM |

| NL8 | Teeth:36/45 D=140MM D1=D2=96MM L3=72MM |

| NL9 | D=175MM D1=D2=124MM L3=93MM |

| NL10 | D=220MM D1=D2=157MM L3=110MM |

Company Information